AF&PA

AF&PA

During this crisis our industry is giving back to help others in need. Hear their stories. Share their stories.

U.S. Paper and Wood Products Industry Sets Record-High Levels of Tissue Production During COVID-19 Pandemic

Nearly 700,000 tons of tissue produced by U.S. mills in March, more than any other month since 2007.

WASHINGTON – American Forest & Paper Association (AF&PA) President and CEO Heidi Brock issued the following statement regarding the U.S. paper and wood products industry’s record-high levels of tissue production in February and March in response to unprecedented demand from COVID-19:

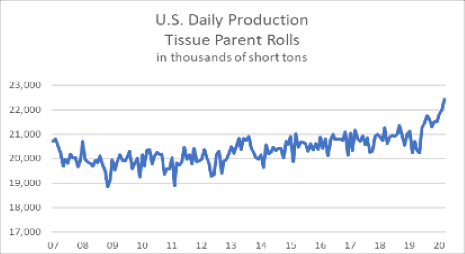

“The men and women who work in the paper and wood products industry continue to do their part to respond to demand for products like bathroom tissue and paper towels during the coronavirus (COVID-19) pandemic. United States tissue mills manufactured nearly 700,000 tons of tissue in March, more than any other month since 2007, when AF&PA began collecting related monthly historical data. This rate works out to more than 4 pounds of tissue for each U.S. resident.

“U.S tissue manufacturers also reached a milestone for daily production at a time of unprecedented need. In February and March, AF&PA members safely and reliably delivered more than 22,000 tons of tissue per day – an all-time high for the industry.

“As daily production reached new thresholds, AF&PA member companies stayed the course, delivering sustainable tissue products to meet everyday, essential needs. I am heartened by the industry’s commitment to safety, and its ability to move products to the global market – just as we do 52 weeks each year.”

In February and March, AF&PA members safely and reliably delivered more than 22,000 short tons of parent roll tissue per day – an all-time high for the industry. In March alone, tissue mills produced nearly 700,000 short tons of parent roll tissue, more than any other month since 2007. This rate works out to more than 4 pounds of tissue for each U.S. resident.

Source: The American Forest & Paper Association

Additional background:

What is tissue and how is it made? Tissue paper products – which include bathroom tissue, paper towels and napkins – are products that contribute to improved personal hygiene, comfort and convenience. Parent tissue is made on paper machines in large rolls that are ultimately converted into various configurations of tissue products. These products are inherently sustainable whether made from sustainably managed wood fiber sources or recovered paper or a combination of the two. Demand for tissue products ensures that the resources used to make them will be plentiful for generations to come. For more information on the production process, please visit AF&PA’s tissue products page: https://www.afandpa.org/our-products/tissue

Where does parent roll tissue end up? Large, parent rolls are created on paper machines and are then converted into individual rolls or folded into sheets by in-house converting operations or by third-party converters. Once converted, the various tissue products are wrapped, packed and shipped utilizing the individual company and customer logistics, based on individual orders to retailers or other institutions like hospitals, schools, or restaurants.

About AF&PA:

The American Forest & Paper Association (AF&PA) serves to advance a sustainable U.S. pulp, paper, packaging, tissue and wood products manufacturing industry through fact-based public policy and marketplace advocacy. AF&PA member companies make products essential for everyday life from renewable and recyclable resources and are committed to continuous improvement through the industry’s sustainability initiative — Better Practices, Better Planet 2020. The forest products industry accounts for approximately four percent of the total U.S. manufacturing GDP, manufactures nearly $300 billion in products annually and employs approximately 950,000 men and women. The industry meets a payroll of approximately $55 billion annually and is among the top 10 manufacturing sector employers in 45 states. Visit AF&PA online at afandpa.org or follow us on Twitter @ForestandPaper.